Renewable Heating and Hot Water

As renewable heating system grow in popularity, and as Government adopt policies that see renewable been specified in preference to the standard fossil fuelled alternatives that we come to relay on over the year, we’re having to adopt to new ways of achieving what we all want from our heating systems – Effective space heating to keep us warm and comfortable in the colder months of the year and reliable supplies of domestic hot water.

Traditionally for most of us, heating systems have been gas or oil boilers – for most of us, combi boilers – driving our heating systems – but legislation is driving these down the pecking order with traditional boilers effectively not installed in new build domestic homes from 2025 and an expectation that legislation will be brought in soon to ban them from being used in replacement heating systems in existing homes – probably by 2035, but possibly sooner. In their places we are seeing the need to install renewable heating systems – in the main, the installation of heat pumps to provide heating and hot water.

Building regulations Part L

As of 15th June, this year in England and from November 2022 in Wales, the interim Building Regulations Part L states that new homes starting construction must produce at least 31% less carbon than under previous regulations. The new Building Regulations are quite complex and are worth taking a closer look at to ensure we understand what they demand of us and to help us to meet these requirements.

The changes to Part L aim to reduce carbon emissions and increase energy efficiency in homes and to start to futureproof them for low carbon heating.

How does Part L affect radiators?

The key figure to bear in mind is 55°C – the maximum flow temperature for all new wet heating systems from this date. The regulations also say that heating appliances and radiators should not be oversized.

TRVs need to be fitted to every radiator except where there is a room thermostat fitted. The differential between the flow and return should be 10°C – giving a 45°C return, and a mean water temperature of 50°C. The expectation is that the next upgrade in Building Regulations Part L will be in 2024 in advance of the new regulations that will come into force in 2025 called the “The Future Homes Standard” where for new build properties there will be a requirement for a significant 75-80% reduction in carbon emissions compared to current regulations.

Do radiators work with low temperature renewable heating systems?

More than 90% of all homes in the UK are heated by radiators and despite what you may have read, that will continue to be the case.

Radiators work well with renewable heating systems and as has always been the case, the key issue is to size them properly for each room they will be heating.

It is true that with lower water flow temperatures, the radiators will need to have a higher heating capacity – either be larger in size of the new K3 – three panels and three fins – type design of radiator or be replaced with vertical radiators that take up a smaller horizontal footprint but can clearly be larger radiators as they can be fitted from floor to ceiling in most rooms. With better levels of insulation and correct sizing of radiators, radiators will be as effective at sharing heat around the home as they always have been. Many large new build developers have already decided to continue with radiators as the main form of heating in their new homes beyond 2025.

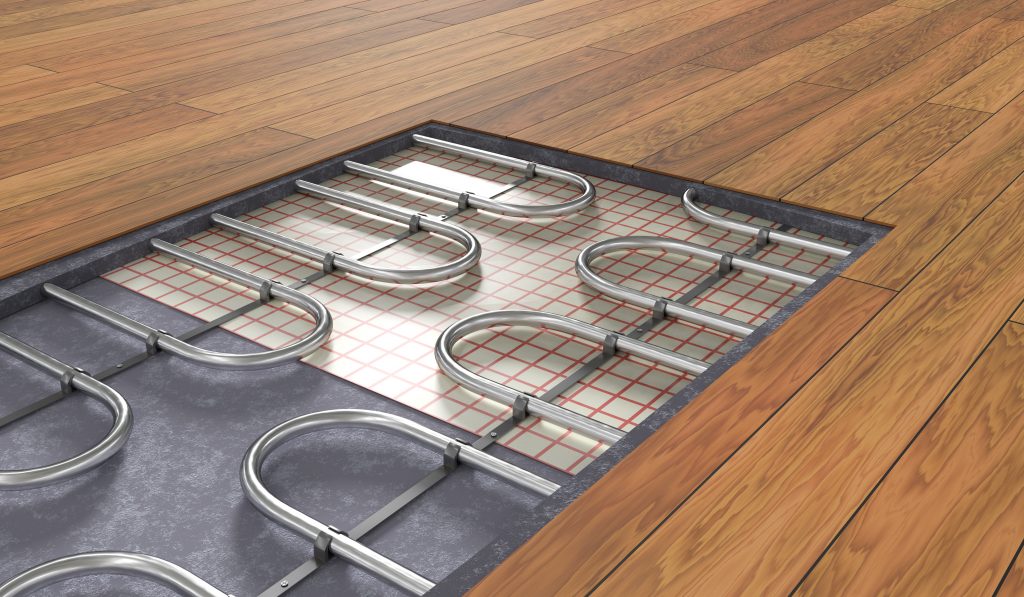

How does underfloor heating with a heat pump work?

Water underfloor heating, also known as hydronic underfloor heating, works by circulating warm water through pipes beneath the floor to heat the room:

- Pipes: A network of pipes are installed beneath the floor.

- Heat source: The pipes are connected to a central manifold that receives hot water from a heat source, such as a boiler or heat pump.

- Thermostat: A thermostat monitors and controls the temperature to maintain a consistent warmth.

- Insulation: The floor is insulated to prevent heat from escaping.

Water underfloor heating has several advantages, including:

- Energy efficiency: Water underfloor heating can be more energy efficient than other heating methods.

- Even warmth: The floor acts as a large radiator, providing even warmth across the room.

- Discreet: The pipes are hidden beneath the floor, so they don’t take up wall space.

Water underfloor heating best suited to new-build properties. The time it takes for the floor to warm up also depends on the type of flooring:

- Hard flooring: Stone, marble, ceramic tiles, and polished screed are thermally conductive and warm up quickly, often within 30–60 minutes.

- Thicker materials: Hardwood and carpets can take several hours to warm up.

To run a water underfloor heating system efficiently, it’s best to run it continuously throughout the winter months.

The Importance of Heat Loss Calculations When Installing a Heat Pump

Heat pumps are gaining popularity in the UK for efficient and sustainable home heating. However, a proper room-by-room heat loss calculation is essential for an effective heat pump system.

Why is Heat Loss Calculation Important?

Traditional boilers produce high temperatures but may not be energy-efficient. In contrast, heat pumps have lower capacity outputs and require precise sizing to avoid under or over-sizing, which can lead to inefficiency, discomfort, and higher costs. Accurate heat loss calculations ensure the heating system is efficient and effective, maintaining comfort while minimizing energy use and costs.

How is a Heat Loss Calculation Performed?

Heat loss calculations, crucial for sizing heat pumps and meeting MCS compliance, follow CIBSE guidelines and standards like the Domestic Heating Design Guide 2014 and EN 12831. Factors considered include:

- External Temperature: More heat loss occurs at lower temperatures.

- Room Temperatures: Different rooms require different temperatures.

- Building Fabric: Construction and insulation details affect heat loss.

For new builds or renovations, calculations use architectural plans and construction details. For existing properties without plans, an onsite survey is required.

A room-by-room heat loss calculation is vital for an efficient heat pump system. This ensures the correct sizing of the heat pump and heating distribution, leading to optimal performance and cost-efficiency.

Understanding Radiator Sizing and Heat Loss Calculations

As part of air source heat pump survey TM Refrigeration Ltd also provide the full measurements of existing radiators and the room available for future changes. We understand the importance of sizing radiators correctly with air source heat pump and our professionally trained office staff specialise in heat loss calculations. This allows them to accurate calculate the correct radiators needed for the designed flow temperature of the ASHP that has been selected for the job.

Why Use TM Refrigeration Ltd For Your Heat Loss Calculations?

- Complete room-by-room heat loss calculations for the full property

- A detailed heat loss summary

- Required emitters with outputs at the required flow temperature

- Details of the proposed equipment

- MCS035 Model Performance Estimation

- MCS020 Sound Calculations

- MCS Compliance certificated

- Recommended equipment

- Any site-specific recommendations

TM Refrigeration Ltd offers this service starting at £250 + VAT for properties up to 300m², a worthwhile investment considering the significant costs of heat pump installation. Contact TM Refrigeration Ltd for a fully MCS compliant heat loss calculation.

Customer Reviews

Rated 5.0 ★★★★★

❝ Excellent service from start to finish. Reliable and professional. Highly recommend! ❞

— Trustpilot Review

❝ Very knowledgeable team. Great advice and quick installation. ❞

— Yell.com Review

❝ Prompt, friendly and competitive pricing. Great experience overall. ❞

— Trustpilot Review

❝ Friendly and professional service. The installation was seamless, and the team was very knowledgeable. ❞

— Yell.com Review

❝ Outstanding customer service and attention to detail. The team went above and beyond to ensure our needs were met. ❞

— Google Review

❝ Efficient and high-quality service. Would not hesitate to use again. ❞

— Google Review